Balancing Instrumentation

Features

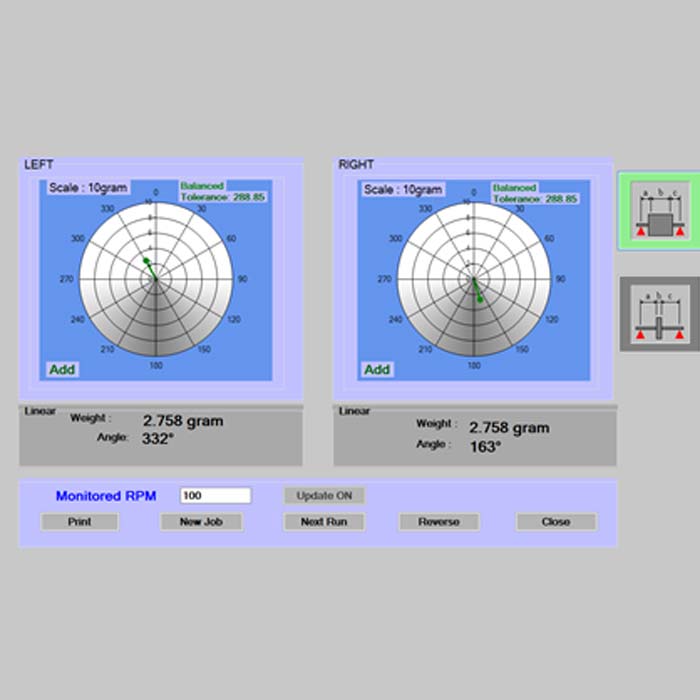

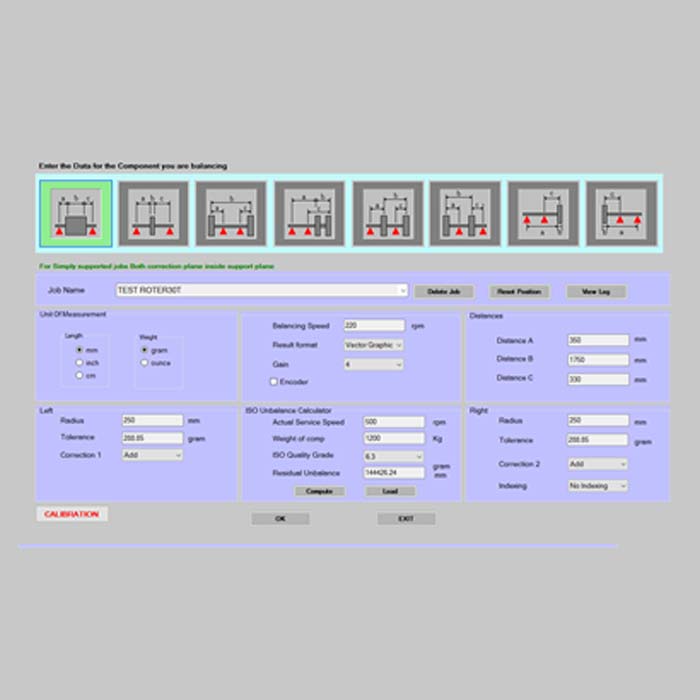

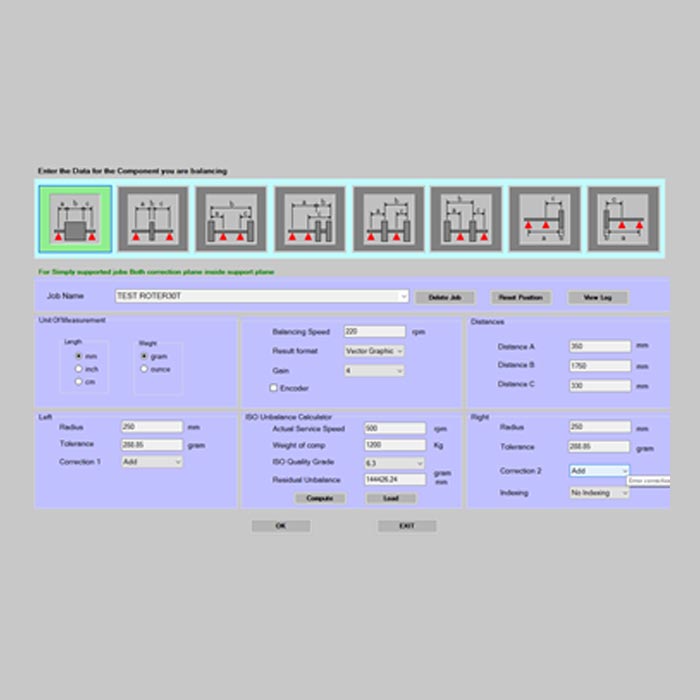

PROTEQ Hard Bearing Dynamic Balancing Machines employ robust roller carriages to convey the centrifugal forces generated by the unbalanced rotor. This force is resisted by the piezoelectric sensors mounted on the pedestals of the Balancing machine. They produce an electrical charge signal proportional to the centrifugal force. This is further converted in to a voltage signal and conditioned by using electronic circuits for further processing to compute the amount of unbalance directly in grams.

Angle of unbalance is measured by infra red sensors using digital phase relation loop technology. This phase generator produces electrical pulses that provide a feedback of rotor speed and zero degree orientation with digital smoothness after computing its phase difference with the unbalance signal derived from the force measuring electronics to display the angle of unbalance.

The rotor support pedestals of horizontal machines and sensor bridges of vertical machines are robust rugged and incorporate an integrated approach in the design of the force measuring system.

This is superior to other designs and provides higher rigidity and accuracy, which are vital for efficient operation. The roller carriages & bridges are designed to accommodate a large variety of rotors with widely varying journal diameters. The entire support system is built to withstand significant overloading and yet retain a high order of achievable accuracy.

We undertake retrofitting of dynamic balancing machines of any make with our instrumentation.